Mooring is a high risk operation. Everyone in shipping industry understands the complexity of mooring, anchoring or towing operations. Mooring lines breaking (Snap back) and Rope bight are cause of mooring line accidents. Poor or no maintenance on mooring equipment has led to accidents.

The size of ships is increasing. Correct brake adjustment and brake lining wear awareness are two important factors for safe operation of cable lifter brake and winches brake performance.

The safety of mooring operations is addressed in SOLAS Reg.II-1/3-8 and amendments have entered into force from 1 January 2024. Two new guidelines are created.

The MSC.1/Circ.1619, which will affect new buildings.

The MSC.1/Circ.1620, will affect existing vessels.

The MSC.1/Circ.1175/Rev.1 Revised Guidance on shipboard towing and mooring equipment.

The new fourth edition mooring equipment guidelines (MEG4) was issued in July 2018 initiating new expression such as the ‘Ship Design MBL’ (SDMBL), ‘Line Design Break Force’ (LDBF) and ‘Working load limit’ (WLL) which are now frequently used in regulations and guidelines.

All vessels in service must maintain documented procedures, operation and maintenance of mooring equipment as per PMS. The PMS must have periodic inspection of mooring lines and mooring line tails and Manufacturers criteria for replacement of mooring lines (Ref. MSC.1/Circ.1620 paragraph 4.3.1 and 5.1).

Vessels built before 2007 will need to have appropriate documentation to determine the original Ship Design MBL. If not available, the mooring winch Brake Design Load (brake holding capacity) must be determined from the manufacturer’s certification. From that the Ship Design MBL can be determined, which will be 125% of the mooring winch designed brake maximum holding load.

Owners are advised to check strength of mooring equipment and their supporting hull structures based on MSC.1/Circ. 1175/Rev.1 (or IACS Rec 10).

The brake rendering should always be set to 60% of the ship design MBL. This brake render set point is the main protection for a ship’s mooring system. It protects all parts of the mooring system. The mooring winch brake becomes a weak link within the mooring system.

A new generation of “smart ropes” equipped with sensors to transmit physical status is also emerging. There are also now ropes available with snap back arrestor.

It is generally seen that condition of windlass and mooring winch equipment is neglected as this is heavy equipment.

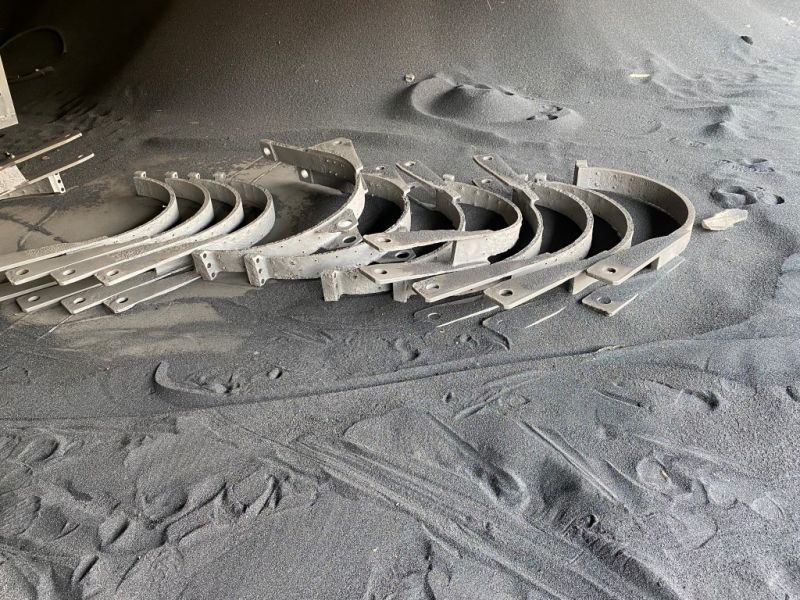

Vessels planned for dry dock must have windlass and mooring equipment inspected thoroughly including replacement of bearings & brake linings, winch band brake sand blasting, inspection of SS drum liner, overhaul of hydraulic brake cylinders, hydraulic motors, gear box inspection, spot derusting of winches & structures, winches brake testing (Rendering test) and SWL marked correctly on supporting hull structures.